Mortar is a mixture of sand and cements that is most often used to build brick or block walls. While that may sound like the same recipe used to make concrete, there are some intentional differences between the formulations for mortar and cement, which is why the materials should not be used interchangeably.

What is the difference between mortar and cement?

If portland cement concrete is one of the most widely used building products in the world, masonry mortar is close behind. Like concrete, mortar is also designed to be durable, but achieves its goal through finesse. Its strengths are quite low compared to concrete and it is never used in thick applications. It is much creamier and more workable than concrete.

If you play tennis, think of concrete as your most powerful serve when you are trying to smash the ball into or through your opponent so that they can’t return the serve. Then think of mortar as a very gently placed lob close to the net that gets your opponent leaning the wrong way with no chance of returning the ball. Both achieve the desired result of earning you a point. The point of this long-winded analogy is to let you know that using concrete and mortar interchangeably will lead to disaster.

How To Mix Mortar

Mortar can be made in one of two ways. The older method is to take portland cement, add hydrated lime and mix with fine sand. The newer method is to use masonry cement and fine sand. Masonry cement is simply a material made by most cement companies where they intergrind the portland with lime or other ingredients designed to produce high air content in a kiln. The results are the same. If you go to the store and buy a bag of mortar you will not be able to tell which method was used to make the masonry cement. There are some parts of the country where masonry cement is simply not available and you will only get portland/lime mortar. The good thing is that it doesn’t matter. Some masons will absolutely swear that you must use portland/lime while others insist masonry cement is the way to go. Just chalk it up to personal preference.

There are three things that make mortar very different from concrete

- Mortar has lower strengths than concrete

- Mortar must have the ability to retain water

- Mortar has a high air content compared to concrete

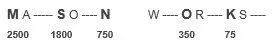

There are three widely produced types of mortar: Types M, S and N. Type M will achieve a compressive strength of 2500 psi at 28 days. Type S will yield 1800 while Type N yields 750. By way of reference most general concrete is in the 4000 psi range but can go as high as 8000 psi for special applications. The easy way to remember the strengths is by spelling out the word MASON WORKS.

Types O and K are not made commercially and can only be used for non-structural applications such as fixing old mortar that has fallen out.

Why isn’t mortar as strong as concrete?

Why not make mortar as strong as concrete? Shouldn’t all materials be as strong as possible? When you build a wall, you want the block or brick to be the strongest part of the wall. When the wall shifts, and almost all do over time, the weakest part is going to break. If the brick or block were to break, then the fix would be building a new wall. If the mortar crumbles, provided you don’t let it go on for years, you simply need to repoint the wall (replace mortar in areas where the old mortar fell out). This is a simpler and more inexpensive fix. One important reason why masonry cement or a portland/lime blend works well in a mortar joint and straight portland does not is the high air content. When temperatures dip below freezing, the water content in mortar freezes. As we know, frozen water takes up more space than liquid water. This means that it will expand and crack whatever is next to it. By intentionally putting lots of tiny air bubbles in the mortar, the expanded ice has somewhere to go without causing damage. Concrete generally has enough mass that this isn’t a problem.

Mortar must also be able to retain water for a certain period of time. Most masons mix up enough mortar to be able to lay a good amount of brick or block without having to stop and mix more. If the mortar they mixed doesn’t retain its flowable nature for at least an hour, the mason will simply add more water to bring it back to life. While this is a really bad idea, it is done in the field all of the time. The problem with this is that the strength of the mortar is designed around certain water to cement ratio. If the ratio is skewed, then so are you when the walls fail due to weak mortar.

Which Type of Mortar Should I Use?

So which mortar should I use? Commercial jobs will usually state which you are required to use. For non-specification work, Type S is usually a safe bet and is what most of you would use on your projects. For those who have a quest to know more, the best general rule is that if the wall is non load-bearing, such as a divider wall inside of a building, then Type N is sufficient. If the wall is below grade or carrying the load of the roof or several stories of brick or block use Type S. Type M is rarely called for and only used in certain large commercial projects.

Regardless of the type of project, we recommend using our sister brand, Amerimix. While Sakrete mortars are excellent, Amerimix pre-blended mortars, stuccos and grouts have additional chemistry to extend board life, improve adhesion and simply be a more mason-friendly mix. Learn more about the Amerimix portfolio at Amerimix.com.