Pro Tip

The Difference Between Mortar and Cement

Mortar is a mixture of sand and cements that is most often used to build brick or block walls. While that may sound like the same recipe used to make concrete, there are some intentional differences between the formulations for mortar and cement, which is why the materials should not be used interchangeably.

What is the difference between mortar and cement?

If portland cement concrete is one of the most widely used building products in the world, masonry mortar is close behind. Like concrete, mortar is also designed to be durable, but achieves its goal through finesse. Its strengths are quite low compared to concrete and it is never used in thick applications. It is much creamier and more workable than concrete.

If you play tennis, think of concrete as your most powerful serve when you are trying to smash the ball into or through your opponent so that they can’t return the serve. Then think of mortar as a very gently placed lob close to the net that gets your opponent leaning the wrong way with no chance of returning the ball. Both achieve the desired result of earning you a point. The point of this long-winded analogy is to let you know that using concrete and mortar interchangeably will lead to disaster.

How To Mix Mortar

Mortar can be made in one of two ways. The older method is to take portland cement, add hydrated lime and mix with fine sand. The newer method is to use masonry cement and fine sand. Masonry cement is simply a material made by most cement companies where they intergrind the portland with lime or other ingredients designed to produce high air content in a kiln. The results are the same. If you go to the store and buy a bag of mortar you will not be able to tell which method was used to make the masonry cement. There are some parts of the country where masonry cement is simply not available and you will only get portland/lime mortar. The good thing is that it doesn’t matter. Some masons will absolutely swear that you must use portland/lime while others insist masonry cement is the way to go. Just chalk it up to personal preference.

There are three things that make mortar very different from concrete

- Mortar has lower strengths than concrete

- Mortar must have the ability to retain water

- Mortar has a high air content compared to concrete

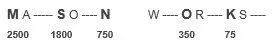

There are three widely produced types of mortar: Types M, S and N. Type M will achieve a compressive strength of 2500 psi at 28 days. Type S will yield 1800 while Type N yields 750. By way of reference most general concrete is in the 4000 psi range but can go as high as 8000 psi for special applications. The easy way to remember the strengths is by spelling out the word MASON WORKS.

Types O and K are not made commercially and can only be used for non-structural applications such as fixing old mortar that has fallen out.

Why isn’t mortar as strong as concrete?

Why not make mortar as strong as concrete? Shouldn’t all materials be as strong as possible? When you build a wall, you want the block or brick to be the strongest part of the wall. When the wall shifts, and almost all do over time, the weakest part is going to break. If the brick or block were to break, then the fix would be building a new wall. If the mortar crumbles, provided you don’t let it go on for years, you simply need to repoint the wall (replace mortar in areas where the old mortar fell out). This is a simpler and more inexpensive fix. One important reason why masonry cement or a portland/lime blend works well in a mortar joint and straight portland does not is the high air content. When temperatures dip below freezing, the water content in mortar freezes. As we know, frozen water takes up more space than liquid water. This means that it will expand and crack whatever is next to it. By intentionally putting lots of tiny air bubbles in the mortar, the expanded ice has somewhere to go without causing damage. Concrete generally has enough mass that this isn’t a problem.

Mortar must also be able to retain water for a certain period of time. Most masons mix up enough mortar to be able to lay a good amount of brick or block without having to stop and mix more. If the mortar they mixed doesn’t retain its flowable nature for at least an hour, the mason will simply add more water to bring it back to life. While this is a really bad idea, it is done in the field all of the time. The problem with this is that the strength of the mortar is designed around certain water to cement ratio. If the ratio is skewed, then so are you when the walls fail due to weak mortar.

Which Type of Mortar Should I Use?

So which mortar should I use? Commercial jobs will usually state which you are required to use. For non-specification work, Type S is usually a safe bet and is what most of you would use on your projects. For those who have a quest to know more, the best general rule is that if the wall is non load-bearing, such as a divider wall inside of a building, then Type N is sufficient. If the wall is below grade or carrying the load of the roof or several stories of brick or block use Type S. Type M is rarely called for and only used in certain large commercial projects.

Regardless of the type of project, we recommend using our sister brand, Amerimix. While Sakrete mortars are excellent, Amerimix pre-blended mortars, stuccos and grouts have additional chemistry to extend board life, improve adhesion and simply be a more mason-friendly mix. Learn more about the Amerimix portfolio at Amerimix.com.

Comments (72)

My sidewalk edges are deteriorating due to using ice melt in the winter what product do you recommend to repair these edges?

Jim, a product like Fast Setting Cement Patcher would work great, assuming the damage is under 2″ in depth.

Check out this Pro Tips guide for more info on how to tackle that project.

Is there any benefit to use type N mortar compared to type S? Such as cracking, water resistance, adhesion etc? If S shrinks less and has greater compressive strength, why would anyone want to use type N for any application ?

Gregory, this is really a question of matching the strength of the mortar to the strength of the block. The rule of thumb is that your mortar should be “softer” (aka weaker) than the block. You want any cracks to propagate through the mortar joint and NOT the block. Mortar can be repaired, block can not!

Type N is typically used for clay brick because of it’s lower (~750 psi) compressive strength. Type S (~1,250 psi) is often stronger than brick, which can actually cause the brick to crack!

Thank you! Excellent article – very helpful.

I am looking for a MORTAR mix to repair i.e. fill in spaces or holes left in the mortar lines where the old has been cracked and fallen out, or has been cracked and needs to be replaced.

The house is 68 years old and I remember the large tray laying on the pre-driveway area where the bricklayer made the mortar.

I have noticed in many repairs to other brickwork and mortar fixes, that the use of what appears to be a cement mix has been used; the colour being light gray versus our browner and coarser sandy colour , and, the size of sand being very fine versus our more coarse. our face brick does not support anything else except its 8-9 foot height, on 8 inch concrete block foundation.

My question is; What mix is going to be the best colour and texture match to our mortar lines which will best make for a quality match? Thank you so very much for this consideration.

John, the color of your mortar is going to be heavily influenced by the color of your SAND. That’s the dominant ingredient in mortar, so it sounds like your mission is going to be finding a good mason sand that matches the color you’re looking for and then mixing your own!

I’m pouring a slab for my generator and have some extra mortar. Can I combine mortar mix and concrete mix together? – 12 bags concrete with eight bags mortar

Michael, we wouldn’t recommend doing that. Might work, but no way to guarantee results…and you’re going to want that generator slab to hold up!

How can concrete be protected from salts, acids and other harmful agents?

Like wood is protected by using paint, or metal is protected by using wax on an automobile.

George, any basic concrete sealer is all you need! Sakrete sells a couple: Cure ‘N Seal and Paver Sealer – both will work great!

Very informative, thank you for the knowledge that I didn’t have prior to reading this.

Hi, I am looking for a product to make bricks with. because i have a lot of river rock i was planning on using them for displacement in the bricks.

Ryan, if you’re talking about CONCRETE brick, you could use pretty much any full-depth mix (assuming they’ll be more than 2″ thick).

i am setting a 4′ x 3′ shower base . Probably an inch of sakrete mortar mix type S. I have an 80 pound bag. Can you tell me what 80 pounds will cover?

Fred, we’d actually recommend a product like Floor Mud or Sand Mix for shower bases. You’d need about 5x 50# bags for the project you’re describing.

Give us a call at 866-SAKRETE and let’s dig into this one together!

I have 30” high brick “sea wall” on a concrete footing at Lake Hamilton in Arkansas.

The lake level is drawn down annually from Nov thru Feb which fully exposes the wall for inspection. I am missing a few brick low on the wall and see many areas where the mortar has fallen out and small grass roots have come thru.

I power washed the wall and removed the roots and now would like to know which mortar I should use for these repairs.

Thank you,

John

John, assuming this is clay brick, we’d recommend Type N mortar. If it’s concrete brick, go with Type S!

I am working on a special project and I don,t expect youth know the answer. but if anyone’s 2 cents is worth its weight in gold it is yours. I am going to enclose a stainless steel time capsule in either cement or mortar and bury it at sea (dump it in the ocean). I would like for the cement mortar to break up in 200 years or better. so that when the cement breaks down the capsule will wash ashore. I want the cement or mortar to hold up at least 200 years……if it holds up longer even better. what is the best product to use. If you cant answer I understand. this is not your everyday construction project. I thank you for any comments you may have for this project. thanks frank azzopardi

Frank, that is a VERY interesting question, but unfortunately way above the level of concrete chemistry we get into around here.

Way too many variables to consider to give you a straightforward answer…but gut says that you’d want something very dense and high-strength like a Precision Non-Shrink Grout. Not sure she’ll make it 200 years in salt water, but it’d definitely give it a run for it’s money!

200 years in the ocean might become 2 million. From what little I know of seas,there is a thing called deposition. Thinks sandstone and fossils. I would get a local oceanography expert to find a good spot.

Thanks for the update was very helpful.

Thanks for the update was very helpful.good to know before using.

Type O and K are absolutely structural. Historic buildings used these lower strengths because it is more permeable, and mortar is really only glue designed to hold bricks together. Bricks make the strength of a wall, while mortar glues them together and allows the wall to breathe and dry out.

Im going to repoint a very large and tall sandstone retaining wall on my property. I live in south central Pennsylvania, where winters can be very cold. I’ve seen so many conflicting opinions about what mortar to use, ranging from Lime mortar to portland and sand, and anything in between. Could you help to clear up some of the confusion around suitable material for the repair to my wall? The mortar is currently very cracked, with many loose stones. It was built around 1955, and has received little attention since then.

Elizabeth, hope we can clear this up a bit. The most important consideration isn’t the mortar “formula” (eg. Portland, lime and sand vs. masonry cement and sand), but the strength. Because sandstone is a very soft material (as far as stone goes), you want to use a similarly “soft” mortar.

We’d recommend looking for a specialty mortar called “Type O”, which is sometimes also called “tuckpointing mortar”. You’re not typically going to find this at a big box retailer – you may need to call your local masonry supply yard.

Give us a call at 866-SAKRETE if you’d like to talk through this one more!

A gap has developed over the years between bricks that are a boundary on a patio,,,what should I use, the gap is 1/4 inch

Gregory, that depends on the material that was originally holding the bricks together. The easy solution is a flexible polyurethane sealant, but you might also consider “tuck pointing” with a Type N mortar.

If you have photos or more information, shoot us a note on social or call us at 866-SAKRETE!

Excellent 👌

This is so interesting. Thank you. Do you have any suggestions of books I can read to start learning more about this topic.

Hello, I live in Ottawa, Canada so the freeze/thaw cycle is important in choosing the correct cement. I have a 30 foot by 4 foot flagstone walkway, 2001. The 6″ reinforced concrete slab has held well. One inch thick stone/slate was laid into “NORMAL PORTLAND CEMENT MORTAR”, with joints between stones filled with “CEMENT MORTAR” – I do not know what the composition was of these two “CEMENTS” but they have broken down into sand, by the looks of it.

Request: Are you able to advise on the exact cement I should use to re-lay the stones and fill in the joints between the stones?

Many thanks

Not sure we’re going to be able to figure out what the old material is, but easy recommendation for a new product! Typically Sand Mix is the go-to for paver bedding, and it can also be used to grout the joints between the stones by mixing the product and applying with a grout bag.

I recently had my brick chimney rebuilt by a masonry contractor. At the top of the chimney, where the flues penetrate, he capped it with a 2-3″ thick layer of what I think is Type S masonry cement. I’m seeing some cracks start to develop. From the article above, I suspect this layer may have been too thick for this cement. What would you recommend, is there a good way to seal those cracks?

If you’re just talking about minor cracks, that’s just a curing issue and is likely superficial. If you’re looking at anything over a hairline, it would be smart to seal it with a polyurethane sealant or potentially parge coat it with something like Top ‘N Bond.

This is a really excellent article. There are so many myths floating around about mortar and none of them are based on any kind of science.

Appreciate that – we’re all about the hard facts here!

I have an old house. I used sakrete with color added to match my clay bricks. I cannot remember what type I used (old moment for sure) I need to do more as the bricks need to be repointed. Can you tell me what type of sakrete you would recommend. Thank you very much. Just so you know, it was a lot of fun to do the work myself.

Assuming you’re talking about repointing bricks, we’d recommend going with a Type N mortar. That’ll be the easiest to work with and most compatible with brick.

A load of fun for sure, but hats off for tackling it yourself!

My friend has a brick sidewalk in southern PA. Many of the joins need to be replaced. Since this brickwork is horizontal instead of vertical, should we use concrete or Portland cement? What is your recommendation? He just bought the house last year and we don’t know what was used originally.

Thanks

The aggregate in concrete is likely going to be way too large to fill those small gaps – would consider using a mortar (Sand Mix, or Type S) applied with a piping bag. Just make sure to remove ALL old joint material before you start.

I am trying to stabilize an old sandstone foundation corner on a New England home from the outside of the house (inside is inaccessible). From digging below grade a bit, the large stones are sill in place but with the old mortar washed out fairly large gaps left. I saw that Type O mortar was recommended for this type of repair, but I wondering if “plasticizers” or super plasticizers can be safely added to it to allow it to be poured as concrete and fill the gaps, while still protecting the soft stone after curing?

And Thank You for this very useful service!

Ron, that’s an interesting one that I’m not sure we’re qualified to answer quickly. Your solution sounds reasonable, but we’d strongly recommend giving a local historical restoration pro a call for their recommendation.

What is used for driveways and patios? What would be good for walkways in a yard?

Sam, you can never go wrong with Sakrete High-Strength Concrete Mix! It will get the job done and leave beautiful results if poured properly. Check out our Slab Pour Calculator to estimate your next job.

I use a mortar, for my construction blocks. In my retainer wall.

Is it ok to simply use quick dry cement for mortar applications?

Raymond,

Mortar is formulated for minimal shrinkage, so it would not be recommended to use cement in this application.

Thanks for the clear explanation of the difference between mortar and cement! It was helpful to learn about the different types of mortar (M, S, and N) and when to use each one.

In the article, you mention that mortar is creamier and more workable than concrete. Does this mean that mortar is always easier to work with than concrete? Are there any situations where concrete might be easier to use?

Hello, of course! Just a heads up, mortar and concrete have different applications that are not interchangeable. Our goal is to explain in this blog article. Consistency is a large differentiator between the two.

I am having a concrete barrel tile roof replaced. The tile I have selected is the Villa 900 by Westlake. It is a snow white sealed tile. My question is what material should be used to finish the capping tiles and joints, and does it need to be sealed once it is used to complete the installation.

Jack, we recommend you reach out to the experts at the tile company to help out with this. Goodluck!

Nice and simple explanation. Thank you.

I am building a home on the coast in Florida with concrete blocks and in some cases poured concrete foundation. I have noticed all around me that at about 18 to 20 years that the rebar and reinforcing materials as well as lentils and steel beams embeded in concrete begin to corrode and cause spalling….essentially causing a loss of structural integrity much like the big condominium that collapsed in North Miami a year or so ago. What can be added to the concrete and mortar to prevent the salt air and sometimes water from corroding the interior steel structure? This must be a factor on highway bridges as well as the commercial buildings. We need to make the concrete non permeable and water tight and air tight I think. How do we increase the design life to more than 20 or 25 years?

Great article! My cinder block garage – built at unknown year after house construction in 1940 – has large cracks and crumbling mortar. The mortar looks very soft, can be removed with a screwdriver.

I am afraid using a too strong mix for repointing will lead to block failure. Is there a guideline for choosing the mortar (for example knowing the bricks are cinderblock)? I am in Montreal – Quebec region so lots of freeze-thaw and very low temperatures. Thanks!

Elton, we’re glad it was helpful for you! Check out our sister brand Amerimix’s Mortar Types webpage for some insightful information on choosing the right mortar for your projects. It should help answer some questions for you!

The focus on mortar’s workability for laying brick and block walls is helpful. For someone tackling a small brick project at home, are there any recommendations on pre-mixed mortar versus mixing your own dry mortar mix? Las Vegas Foundations

Joey, we definitely suggest using pre-blended mortar mix over making your own batch. A pre-blended mix is faster, cleaner, and produces a better yield. Hope that helps!

Hi I’m looking for more information on what types of cement or mortar for what job. I would like to skim coat a chimney that has already been stuccoed but the stucco is flaking off and I need to repair that, what do I use?

Hi Joseph, we would advise removing the old stucco on the chimney at the moment to have the best results. Type S Mortar would help get the job done in this situation!

Great information. Thanks

Nice to know that in this age of slap dash construction with things like PYRITE in the mix

Aptly described as building with WEETABIX with disastrous results

I have “PVT masonry veneer mortar HB”. Can I use that to re-install a loose stone?

Mabel, absolutely! That would be a great product to use.

I need to match the mortar used for the brick of my house. It’s clearly got a brown coloring so I’m assuming I will need to mix something myself to try to match it.

I’m lost as to what SPECIFIC products of yours I should use. Can you identify by PRODUCT NAME and NUMBER what mortar mix and sand I should get to lay a matching brick wall about 4’x4’?

Phil, let’s help you out here. What you’re looking for is Sakrete Type N Mortar Mix and the closest brown color we have is the Buff in Cement Color. To find the desired color, we suggest testing the colored mortars in test portions. Add some color to the mix, apply to a test area, allow 3 days of dry time and report the dosage. Do this a few times until it meets your needs. Good luck!

What differences will be noticed over time and at the time of install between:

1) starting with type S mortar and adding 3 parts ¼” aggregate and 2) a typical Portland x1 + sand x2, aggregate x3 mix, when laying down either a thin patch ½” to 3” or a small curb (3”x6”)?

Larry, it’s best to not add the 3 parts of aggregate to the Type S Mortar. Traditional concrete mix would suffice, although you could also use Sakrete Top ‘N Bond to get the job done.

Just before you decide to create your own checklist to incorporate an idea associated with what camping checklist ought to Really … A listing can be well over what you need

Understanding the difference between mortar and cement is crucial for any construction project. Mortar, a mixture of sand and cements, is used primarily for building brick or block walls, while concrete is designed for durability in thick applications. Mortar’s lower strength, higher air content, and ability to retain water make it ideal for joining bricks or blocks, ensuring the weakest part of a wall is easier to repair. Always choose the appropriate type for your specific needs to ensure long-lasting .results

I have about 6 to 8 bags of mortar that is sitting in my garage that has not been used in years and I need to have a very small area where I have to add cement slab to put up this small little building on top of it to let my grandkids bikes be stored in the little shelter my question is can be put like in a form adding to the existing slab that I already have to put this small wooden building over top of it

Hi Linda, your best bet is to get fresh new bags. Bagged concrete products have a specific shelf life and using old bags would lead to poor product performance. Feel free to contact our technical support team at 866-725-7383 for help on adding to an existing slab. Good luck!

I have ADD and this was one of the most informative and interesting write ups on…..we’ll mortar, I mean cement, I mean concreate….

Well done, I really hope AI didn’t write this for the sake of humanity. I am a Mason BTW and i just learned a lot in that 5 min read. TY

Chad, this was 100% written by our experts! Glad you were able to learn from this resource. Please feel free to check out our other blogs.