Products Used

Tools Needed

- Graduated bucket

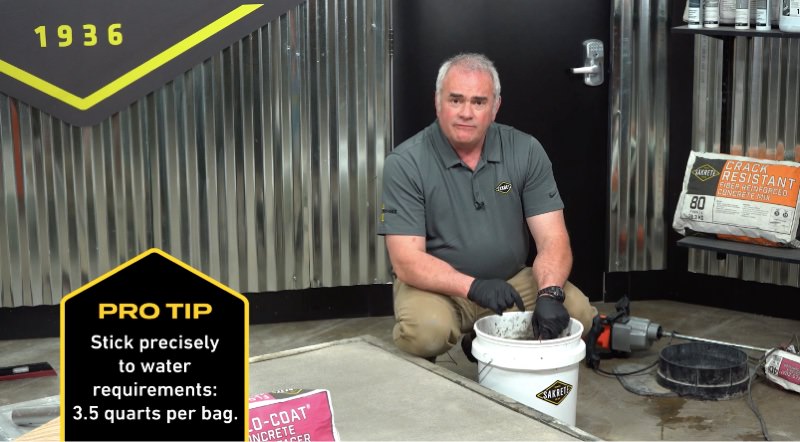

- 5-Gallon bucket for mixing

- Electric paddle mixer

- Long-handled squeegee with a stiff blade

Project Level: difficult

Project Length: 1 Hour

Project Guide – Resurfacing

If you want to breathe new life into an old, damaged slab, then resurfacing is a quick, cost-effective way to do just that—or add a unique decorative finish. Be warned; this is a team project, so make sure to recruit a helper!

To get familiar with how Flo-Coat handles, we recommend testing out a small amount on a piece of plywood or other scrap areas.

Project Tip: If you’re planning to resurface a slab much larger than 36 square feet, break up the project into multiple pours. Use expansion joints as pre-defined stopping points!

Once you add water, it’s important to move quickly! Achieving proper mix consistency is a critical step in a successful Flo-Coat application.

Project Tip: Working in a team makes the job go more smoothly – one person mixing, one pouring and one spreading is ideal!

Remember, speed and teamwork are significant at this stage. Move quickly and trust the material—and yourself! Most importantly, resist the urge to over-work the surface.

Project Tip: Practice makes perfect. Work with Flo-Coat on a piece of scrap lumber before tackling a resurfacing project for the first time. Remember that you can always apply a second layer to correct any defects!

A proper cure procedure is a major step for yielding long-lasting results, so don’t skip it!

Project Tip: Using cold water in hot weather is a great method for extending the working time of Flo-Coat.

Enter An Email To Send These Results.