Pro-Mix All-Purpose Cement Mix

Data SheetTools Needed

- Measuring Tool: Graduated Bucket, Measuring Cups, etc.

- Mixing bucket

- Latex or Nitrile Gloves

- Margin Trowel

- 1 – 2x Flat Trowels

- Paintbrush or Broom for Finishing (depending on size of area)

Project Level: moderate

Project Length: 20 Minutes

Project Guide: Repairing Damaged Pre-Cast Concrete

No precast structure is perfect – even on day one. Whether it’s pop-outs after forms are pulled, dings during transportation or damage from forklifts, precast takes a lot of abuse – so being able to quickly patch, repair and smooth out damage is a must.

Sakrete’s Pro-Mix lineup is the solution. With extended working time, ultra-fast structural strength and 7,000+ psi final strength, it’s the only mix you need to fix a wide range of damage from feather edge up to 4” deep – something few other mixes can boast.

In this project guide, we’re going to tackle three of the most common precast repairs.

Project Tip: Always over-estimate when mixing by eye! It’s difficult if not impossible to mix another batch halfway through, especially when using fast-setting materials.

When working with Pro-Mix products, be sure to only mix as much as can be placed in 10 minutes. Don’t get cocky!

Project Tip: Mixing by hand is most convenient for small patches, especially when mixing to a firm consistency. Be sure to wear gloves!

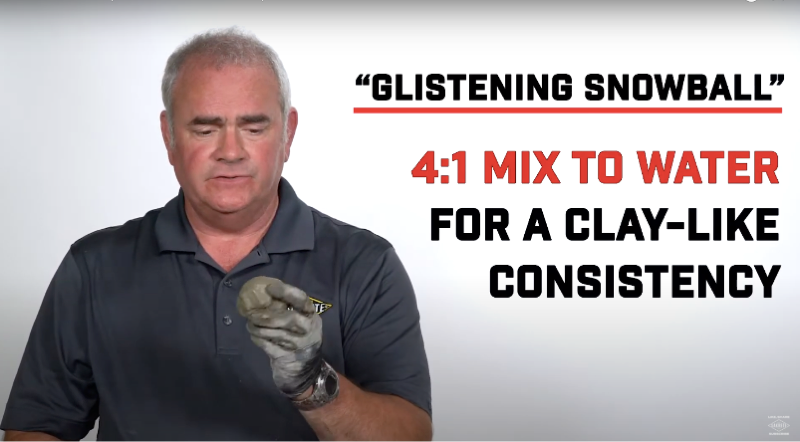

When mixing to a “Glistening Snowball” consistency, application work is done by hand.

Project Tip: Consider skim-coating the entire repair area as a final step to achieve a uniform appearance.

Put the finishing touches on the job.

Project Tip: Applying Sakrete Cure ‘N Seal is an often-overlooked best practice that will ensure the best curing behavior of all concrete – including repair materials.

Enter An Email To Send These Results.